2025-10-15

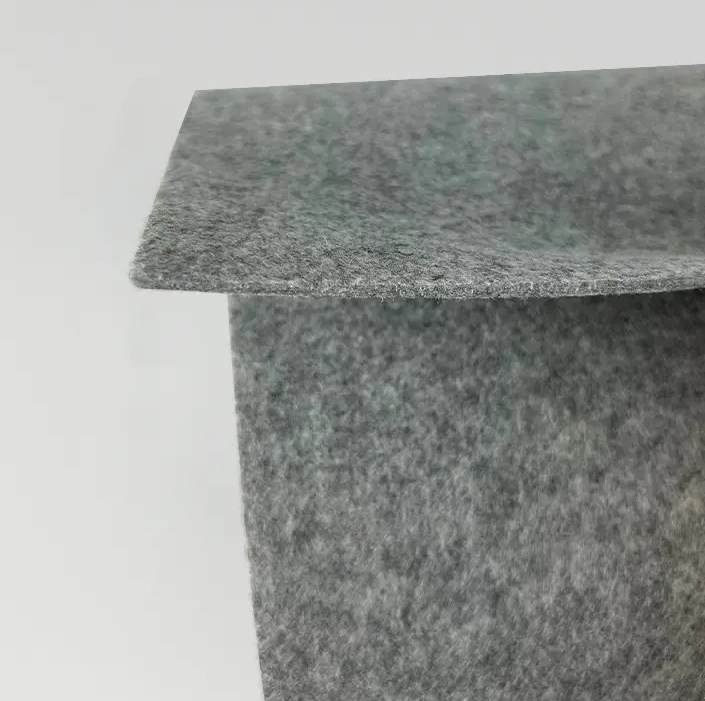

In modern industry and home furnishings, needle punch nonwoven felt, as a unique nonwoven material, is increasingly becoming a key choice in design and manufacturing. Its unique manufacturing process, excellent physical properties, and diverse applications have attracted widespread attention in industries such as textiles, automotive, construction, and home furnishings.

Manufacturing Process and Principles of Needle Punch Nonwoven Felt

The core advantage of needle punch nonwoven felt lies in its unique production process. Unlike traditional textile fabrics, needle punch nonwoven felt combines fiber alignment with mechanical needling to create a tightly interwoven, stable structure. During this process, the fiber orientation and density can be finely tuned by controlling the frequency and depth of the needling, resulting in felts of varying thickness and hardness.

The needling process not only strengthens the physical connection between fibers but also significantly enhances the felt's abrasion resistance and tensile strength. This process, which eliminates the need for spinning and weaving, significantly improves material production efficiency while reducing energy consumption and production costs, meeting modern industry's demand for efficient and environmentally friendly materials.

Material Properties and Performance Advantages

Needle-punched nonwoven felt exhibits numerous physical advantages. Its structural stability is exceptional, maintaining its shape under conditions of heat, humidity, and mechanical friction. This makes it well-suited for applications such as industrial machinery gaskets, automotive interiors, and sound insulation.

Felt is highly flexible and malleable, allowing it to be cut, pressed, or thermoformed to meet diverse design requirements. Compared to traditional fabrics, needle-punched nonwoven felt offers greater control over thickness and density, enabling more precise functional design, such as sound absorption, thermal insulation, or cushioning.

The material's environmental performance is also noteworthy. Many needle-punched felts are produced using recyclable fibers such as polyester and polypropylene through environmentally friendly processes, which not only reduces carbon emissions during production but also allows for the reuse of materials, aligning with the principles of green manufacturing and sustainable development.

Wide Application Value in Various Industries

Needle-punch nonwoven felt has applications across nearly every key area of modern manufacturing. In the automotive industry, it is widely used in interior fabrics, sound-absorbing pads, and chassis protection, enhancing both comfort and safety. In the home furnishing sector, felt is commonly used in furniture lining, carpet backing, and mattress filling, improving the product's texture and extending its lifespan.

The construction industry is also increasingly appreciating the functionality of needle punched felt. Due to its excellent sound insulation, thermal insulation, and shock absorption properties, felt can be used as interior wall partitions, ceiling padding, and floor vibration isolation materials, enhancing overall building comfort and durability. Furthermore, in the industrial sector, needle punched nonwoven felt, due to its wear resistance, corrosion resistance, and high-temperature stability, is used in filter materials, packaging gaskets, and protective materials.

Technological Innovation and Industry Development Trends

With the continuous advancement of materials science and manufacturing technology, the research and development of needle punch nonwoven felt is also undergoing continuous innovation. The diversification of fiber types and the application of composite processes are continuously upgrading the functionality of felt. For example, by adding functional nanomaterials or thermoplastic fibers, it can achieve waterproof, oil-proof, or flame-retardant properties, expanding its application in high-end markets.

Needle Punch Nonwoven Felt, with its unique manufacturing process, excellent performance advantages, and wide application potential, is becoming an important material choice in modern industry and home furnishing. With the continuous improvement of technological innovation and market demand, needle punch nonwoven felt will continue to play a core role in environmentally friendly materials, functional design, and intelligent manufacturing.